- View Mobile Number

marutipanchalcylinders@gmail.com

Facilities

Foundry Facility

Our foundry is fully equipped to serve our costumer requirement and it produces each and every batch with traceability.

Pattern Shop : Our pattern shop is equipped with conventional and CNC Lathe, Milling ,Redial Drilling, Surface Plate and all necessary measuring equipments like Venire, Micrometer, Dial Gauge, Bore Gauge, Height Gauge Etc. Each and every patterns and core boxes are identified and periodically dimensionally inspected and recorded.

Core Shop : Our core shop is following three types of processes Single part self setting hand molding and automatic machines for Hot Box and Cold Box system. All critical raw materials are inspected based on our standardized norms. Each process has its separate area and all core are identified and handled very carefully. We are doing 100% visually inspection and also stage wise dimension inspection and maintaining record.

Shell Moulding Shop : Our Shell Moulding shop has three fully automatic PLC base machines with 600 mm * 600 mm * 300 mm mould size. Our shell shop ensures 100% clean shell and core assembling.

Melting Shop : Our two induction furnace providing 400 KG/Hr molten metal. To ensure specified composition we check molten metal on spectro before pouring and also reserve the specimen samples. Close monitoring over temperature by temperature analyzer.

Fattling Shop : Our fattling shop is equipped with bench grinders, riser cut-off machine, flexible shaft grinder. Casting is cleaned by our shot blast machine. All casting are visually inspected and stage wise dimensionally inspected and maintain record. There are three 13,000 KG ( 5 tones,5 tones,3 tones) capacity bell type to cater different requirement like annealing, Water Quenching, Normalizing. Each furnace cycle has monitored and recorded and produced components has been ensure required hardness as per IS sampling plan on our hardness testing machine.

QC Laboratory : To ensure costumer requirement our spectro meter is calibrated with standard CRM samples and periodically calibrated. Each furnace melt has been assured and final samples has been stored for six month for traceability. We also ensure mechanical properties from NABL approved outside source.

Machining Facilities

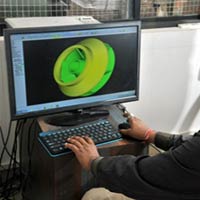

CNC Turning Centers : Our CNC shop is loaded with 13 nos of CNC turning centre max turning dia. 550 mm to satisfy our costumer with finest quality. Each and every operator is trained to produce and measures components as per requirements. We always upgrade our operators to perform well. Our QC team also supervises the production through stage wise inspection and maintain record.

Broaching : There are three vertical broaching machine with the efficiency to 100mm key way length. All the pieces are inspected with gauge and also stage wise inspected and recorded.

Balancing : Three vertical dynamic balancing machines of 10 KG capacity ensure required balancing accuracy of 0.2 grams.

QC Department : Our Qc team is well educated and trained to offers best quality to our costumer. QC department assist with all necessary measuring instruments like venire caliper, micro meter (inside and outside), air gauge, bore gauge and standard ring and also Master slip gauge, between center, RA comparator, radius gauge, bewel protector, thread gauge etc. Other snap, plug etc. All instruments are traceable to NABL certificates and periodic in-house and outside calibration also being done.

Our foundry is fully equipped to serve our costumer requirement and it produces each and every batch with traceability.

Pattern Shop : Our pattern shop is equipped with conventional and CNC Lathe, Milling ,Redial Drilling, Surface Plate and all necessary measuring equipments like Venire, Micrometer, Dial Gauge, Bore Gauge, Height Gauge Etc. Each and every patterns and core boxes are identified and periodically dimensionally inspected and recorded.

Core Shop : Our core shop is following three types of processes Single part self setting hand molding and automatic machines for Hot Box and Cold Box system. All critical raw materials are inspected based on our standardized norms. Each process has its separate area and all core are identified and handled very carefully. We are doing 100% visually inspection and also stage wise dimension inspection and maintaining record.

Shell Moulding Shop : Our Shell Moulding shop has three fully automatic PLC base machines with 600 mm * 600 mm * 300 mm mould size. Our shell shop ensures 100% clean shell and core assembling.

Melting Shop : Our two induction furnace providing 400 KG/Hr molten metal. To ensure specified composition we check molten metal on spectro before pouring and also reserve the specimen samples. Close monitoring over temperature by temperature analyzer.

Fattling Shop : Our fattling shop is equipped with bench grinders, riser cut-off machine, flexible shaft grinder. Casting is cleaned by our shot blast machine. All casting are visually inspected and stage wise dimensionally inspected and maintain record. There are three 13,000 KG ( 5 tones,5 tones,3 tones) capacity bell type to cater different requirement like annealing, Water Quenching, Normalizing. Each furnace cycle has monitored and recorded and produced components has been ensure required hardness as per IS sampling plan on our hardness testing machine.

QC Laboratory : To ensure costumer requirement our spectro meter is calibrated with standard CRM samples and periodically calibrated. Each furnace melt has been assured and final samples has been stored for six month for traceability. We also ensure mechanical properties from NABL approved outside source.

Machining Facilities

CNC Turning Centers : Our CNC shop is loaded with 13 nos of CNC turning centre max turning dia. 550 mm to satisfy our costumer with finest quality. Each and every operator is trained to produce and measures components as per requirements. We always upgrade our operators to perform well. Our QC team also supervises the production through stage wise inspection and maintain record.

Broaching : There are three vertical broaching machine with the efficiency to 100mm key way length. All the pieces are inspected with gauge and also stage wise inspected and recorded.

Balancing : Three vertical dynamic balancing machines of 10 KG capacity ensure required balancing accuracy of 0.2 grams.

QC Department : Our Qc team is well educated and trained to offers best quality to our costumer. QC department assist with all necessary measuring instruments like venire caliper, micro meter (inside and outside), air gauge, bore gauge and standard ring and also Master slip gauge, between center, RA comparator, radius gauge, bewel protector, thread gauge etc. Other snap, plug etc. All instruments are traceable to NABL certificates and periodic in-house and outside calibration also being done.

Contact Us

Maruti Panchal Cylinders Pvt. Ltd.

Block No-629, Moti-Bhoyan Village, Beside Choksi Tube Ltd., Kalol-Khatraj Road, Gandhinagar, Gujarat - 382721, India

Call Us : View Mobile Number